Our Service

Cutting

We specialise in cutting services with wide range of materials up to 1300mm (height).

The materials we can cut to your required sizes include steel plate, round bar and etc.

Cutting specification

Provides raw material cut to size required by our clients

Round bars and Flat bars

Bandsaw and Gas Cutting

Cutting maximum up to 1300mm (H) x 1700mm (W)

Machining

Machining is a process in which a material is cut to a desired final shape and size by a controlled material-removal process. Machining is a process in which a material is cut to a desired final shape and size by a controlled material-removal process.

| Machining | Maximum size | Accuracy |

| Milling | 370mm (H) x 700mm (W)x 1200mm(L) | ± 0.10 |

| Rotary Grinding | 350mm (H) x 1300mm (D) | ± 0.05 |

| Surface Grinding | 550mm (H) x 700mm (W)x 1500mm(L) | ± 0.02 |

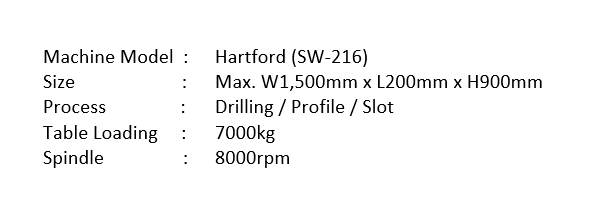

| CNC | 900 (H) x 1500 (W) x 2000 (L) | ± 5micron/300 |

CNC Process

CNC stands for Computerized Numerical Control. It is a computerized manufacturing process in which pre-programmed software and code controls the movement of production equipment.

It can dictates the movement of factory tools and machinery. Using this type of machine versus manual machining can result in improved accuracy, increase production speeds, enhanced safety, increased efficiency and most of all cost savings.

Heat Treatment

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material.

The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass.

HEAT TREATMENT SERVICES

To ensure high hardness and toughness material, we provide heat treatment service

Hardening (for Tools Steel)

To produce the most durable parts with clean surface and minimum distortion.

Stress Relief

To release the stresses induced by rough machining, welding, electric discharge machining (EDM), or accumulated during the extended service, especially by die casting.

Subzero Processing (-180° C) / Sub Zero (-80° C)

To enhance wear resistance and minimise the amount of retained austenite to ensure that tools are highly stable during the service period.

Shot Blasting

To performed after the casting has been remove from the sand mold

Nitriding

To diffuses nitrogen into the surface of a metal to create a case-hardened surface

Annealing

To changes the physical and chemical properties of a material to increase ductility and reduce the hardness to make it more workable

In addition to our technical expertise, our team of senior engineers use the latest testing and measuring equipment to produce international standard quality inspection reports in heat treatment analysis and troubleshooting.

Technical Support

We not only provide our customers with the best products and services, but also provide accurate and user-friendly information, and strengthen partnerships for mutual growth and development.

A Subsidiary company of Daido Steel and Daido DM Steel Solution, we area fully supported by their technologies and long experience. We are constantly developing and innovating tooling solutions, applying our extensive steel knowledge to tools, finished parts, machines and their applications in all industries. Our technical support team will provide recommendations for local steel grades and steel treatments. A material survey as well as a personal phone call or email will provide immediate assistance.

We provide project evaluation error analysis, troubleshooting, and lab services. We have the facilities and expertise to inspect all relevant material properties and provide our clients with reports that are timely relevant to their needs and compliant with international standards. Customized product and application knowledge training can be arranged at your site, at your local sales office or at the steelworks headquarters in Sweden.

Please contact Daido DMS Malaysia and find more about us and our resources. We will glad to help you.